Cellevat3d™ takes nanofibers into the 3rd dimension

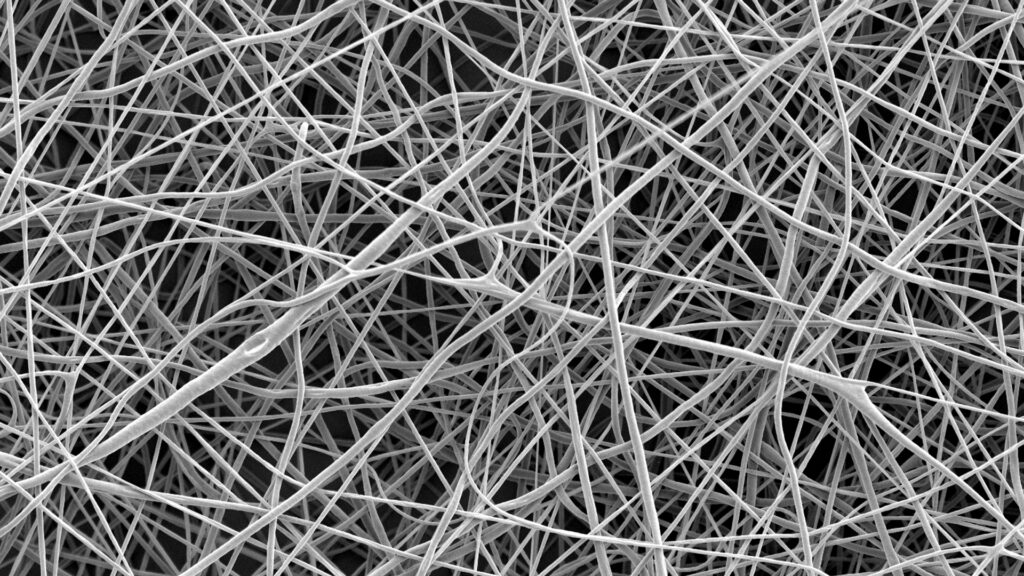

Cellevat3d™ is a game-changing, green, and sustainable, deep-tech innovation for the biopharmaceutical industry. Based on this nanomaterial platform, Cellevate is developing a product portfolio for upstream bioprocessing applications called Cellevat3d™ “carriers”. These are highly customizable micro- and macrocarriers that faithfully replicate the 3D extracellular environment found in the human body and provide up to 60 times larger area for cell growth compared to competing solutions, all while being sustainable and green because of the use of natural polymers. The unique carrier properties are a result of a patent-pending nanofiber scaffold production technology which creates networks of polymer nanofibers that can be handled in a liquid form and prepared into three-dimensional (3D) structures.

Based on research from NanoLund, a world renowned Swedish nanomaterial center, Cellevate has developed into a strong nanotechnology based company with competencies ranging from material science to chemistry, biology and bioprocessing combined with extensive experience in project management and delivering customized nano fiber based cell culture systems to our customers.

Cellevat3d™ nanotechnology based products have already been used and generated results across a range of cell culture applications. Some of the cells used are outlined below:

- Chinese Hamster Ovary Cells (CHO)

- Human Embryonic Kidney Cells (HEK293AD, HEK293T)

- Human Caucasian Carcinoma Cells (A549)

- Human Colon Carcinoma Cells (HCT116)

- Mesenchymal Stem Cells (MCS)

- Induced Pluripiotent Stem Cells (iPSC)

- Hematopoietic Stem Cells (HSC)

- Human Neural Progenitor Cells (HNPC)

- Retinal Post-Natal Cells (RPNC)

- Peripheral Mononuclear Cells (PBMC)

- Human Adipose Tissue-Derived Stem Cells (hASC)

- Fibroblasts (Murine, Human-Dermal, cancer associated)

- Microglia (BV2)

- Breast Epithelial Cells (MCF10A)

- Breast Cancer Cells (JIMT-1)

- Circulating Tumor Cells (CTC)

- Natural Killer Cells (NK)

- Human Neuroblastoma Cells (SH-SY5Y)

- Pancreatic Cancer Cells (MIA PaCa-2)

- Pancreatic Ductal Adenocarcinoma Cells (PDAC)

For more information see Publications

Cellevate’s Cellevat3d™ technology

Technology deep dive

Electrospinning is a fiber production method which uses electric force to draw charged threads of polymer solutions or polymer melts up to fiber diameters in the order of some hundred nanometers.

When a sufficiently high voltage is applied to a liquid droplet, the body of the liquid becomes charged, and electrostatic repulsion counteracts the surface tension and the droplet is stretched; at a critical point a stream of liquid erupts from the surface. This point of eruption is known as the Taylor cone. If the molecular cohesion of the liquid is sufficiently high, stream breakup does not occur (if it does, droplets are electrosprayed) and a charged liquid jet is formed.

As the jet dries in flight, the mode of current flow changes from ohmic to convective as the charge migrates to the surface of the fiber. The jet is then elongated by a whipping process caused by electrostatic repulsion initiated at small bends in the fiber, until it is finally deposited on the grounded collector. The elongation and thinning of the fiber resulting from this bending instability leads to the formation of uniform fibers with nanometer-scale diameters.

The Cellevat3d™ platform adds onto the electrospinning process with a patent-pending technology that enables nanofibers to be handled in a liquid form. The fiber-containing liquid can then be molded into any given shape or form.